About Giwett

Giwett is a B2B manufacturer of PVC decorative films serving interior fit-out contractors, distributors, and furniture makers across the Middle East. With integrated R&D–printing–lamination–coating lines and an independent warehouse, we turn ideas into stable, scalable products fast. Our portfolio covers woodgrain, marble/stone, metallic, fabric texture, brick texture, and soft-touch matte finishes for cabinets, doors, walls, and furniture. We support OEM/ODM, flexible MOQs, and 48-hour sampling, backed by a professional design team and a seasoned export sales network. Low-VOC options and RoHS/REACH-ready materials help you meet project specifications while keeping installation clean, quick, and cost-effective.

Why Choose Giwett

Consistent Quality

Batch color control, adhesion/abrasion checks, and aging tests for reliability.

Compliance & Safety

Low-VOC, RoHS/REACH-ready options and technical data sheets on request.

Design Depth

Hundreds of SKUs plus color/emboss customization for brand-exclusive collections.

Flexible Supply

Mixed-design orders, stock support, and drop-shipping for distributors in MENA.

Fast Turnaround

48-hour sampling and streamlined production shorten project lead times.

Responsive Service

Professional pre-/after-sales guidance—24/7 online with fast, coordinated responses.

Raw Material Control

Giwett runs a vertically managed supply chain for films and adhesives. We approve resin and additive partners through audits, then lock formulas with ERP traceability. Each lot is checked for K-value, moisture, viscosity, and ash before release. In-house calendering produces a stable base with tight thickness, tensile strength, and low shrinkage. Masterbatch ratios are monitored by SPC, and retained samples plus COA records ensure long-term color consistency, printability, and durability across repeat orders.

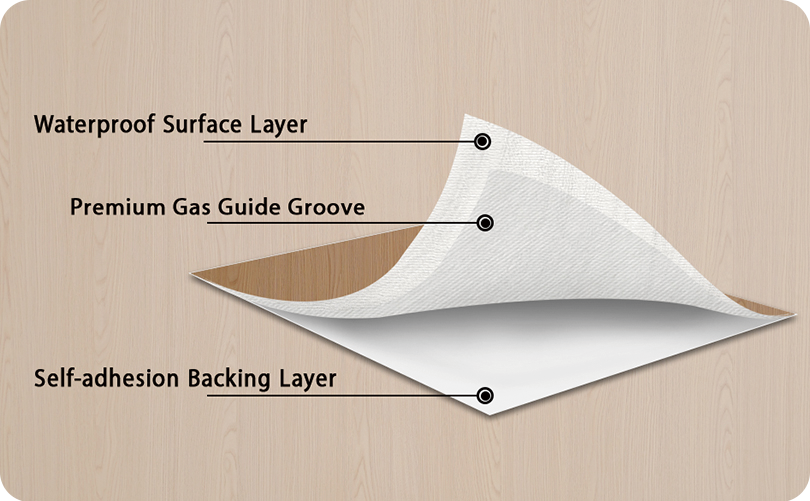

Product Performance

Engineered for real installations, Giwett films are waterproof, easy to clean, and offer strong initial tack with stable long-term adhesion. The calendered base resists impact, tearing, and edge lifting; coatings provide anti-scratch, anti-fingerprint, and stain resistance. UV-stable, low-VOC, and heat-humidity tolerant, our films keep color and texture in high-traffic spaces. Options include fire-retardant and antibacterial grades, enabling durable upgrades for cabinets, doors, counters, and retail interiors.

Advanced Equipment

Our production lines combine servo-driven calendering, precision coating, and laminating with closed-loop thickness control and automatic web alignment. Inline corona treatment, HEPA-level cleanliness, and defect-detection cameras keep surfaces smooth and contamination-free. Digital recipe management locks emboss depth, coating weight, and registration for repeatable results. High-speed changeovers and wide-width runs deliver both fast samples and stable mass production for OEM/ODM projects.

Quality Inspection

Giwett’s QC lab validates every roll against strict specs: thickness/flatness, peel and tensile strength, surface tension for bonding, gloss or matte level, and ΔE color targets. We perform accelerated aging, UV and abrasion testing, and adhesive creep checks under heat and humidity. Each batch receives a QR-linked test report and is traceable to retained samples stored for years. Processes align with ISO-style controls and undergo regular internal audits to maintain continuous capability.