Quality Philosophy at Giwett

At Giwett, quality is engineered at every step. Our closed-loop system spans raw-material approval, in-house calendering, printing, coating, and converting—tracked in ERP with QR traceability. Inline sensors and defect cameras feed SPC dashboards to keep gauge, color, and adhesion stable. Every batch ships with test records for thickness, ΔE color, peel/tensile, surface energy, VOC, and UV/aging—ready for project audits.

-

Quality Assurance (QA): supplier audits, recipe control, training, and preventive plans.

-

Quality Control (QC): incoming/in-process/final checks, lot release, and documentation.

-

Testing Capabilities: mechanical, adhesive, optical, and environmental laboratories.

-

Sustainability Commitment: low-VOC chemistry, waste reduction, energy efficiency, compliance.

Quality Assurance (QA)

-

Supplier & Material Approval: Audits, COA/lot traceability, and incoming checks (K-value, moisture, viscosity, ash).

-

Recipe & Change Control: Locked BOMs and digital “golden samples”; ECN workflow for any formula/emboss change.

-

Process Assurance: FMEA and control plans for calendering, printing, coating, laminating, slitting.

-

Design Verification: Lab pilots for adhesion, color ΔE, and durability before mass production; pre-production run sign-off.

Quality Control (QC)

-

Incoming QC: Resin/additive verification; film base gauge and dyne tests before release to production.

-

In-Process QC: SPC on thickness and color; inline defect cameras; 90°/180° peel & loop-tack sampling per lot.

-

Final QC: Tensile/elongation, shrinkage, surface energy, gloss/matte, abrasion, UV/aging; QR-linked COA.

-

Packaging QC: Clean-room winding, edge protection, honeycomb paper & returnable pallets to prevent transit damage.

Testing Capabilities

-

Mechanical: Tensile/elongation, tear, Taber abrasion, scratch, impact (falling-dart).

-

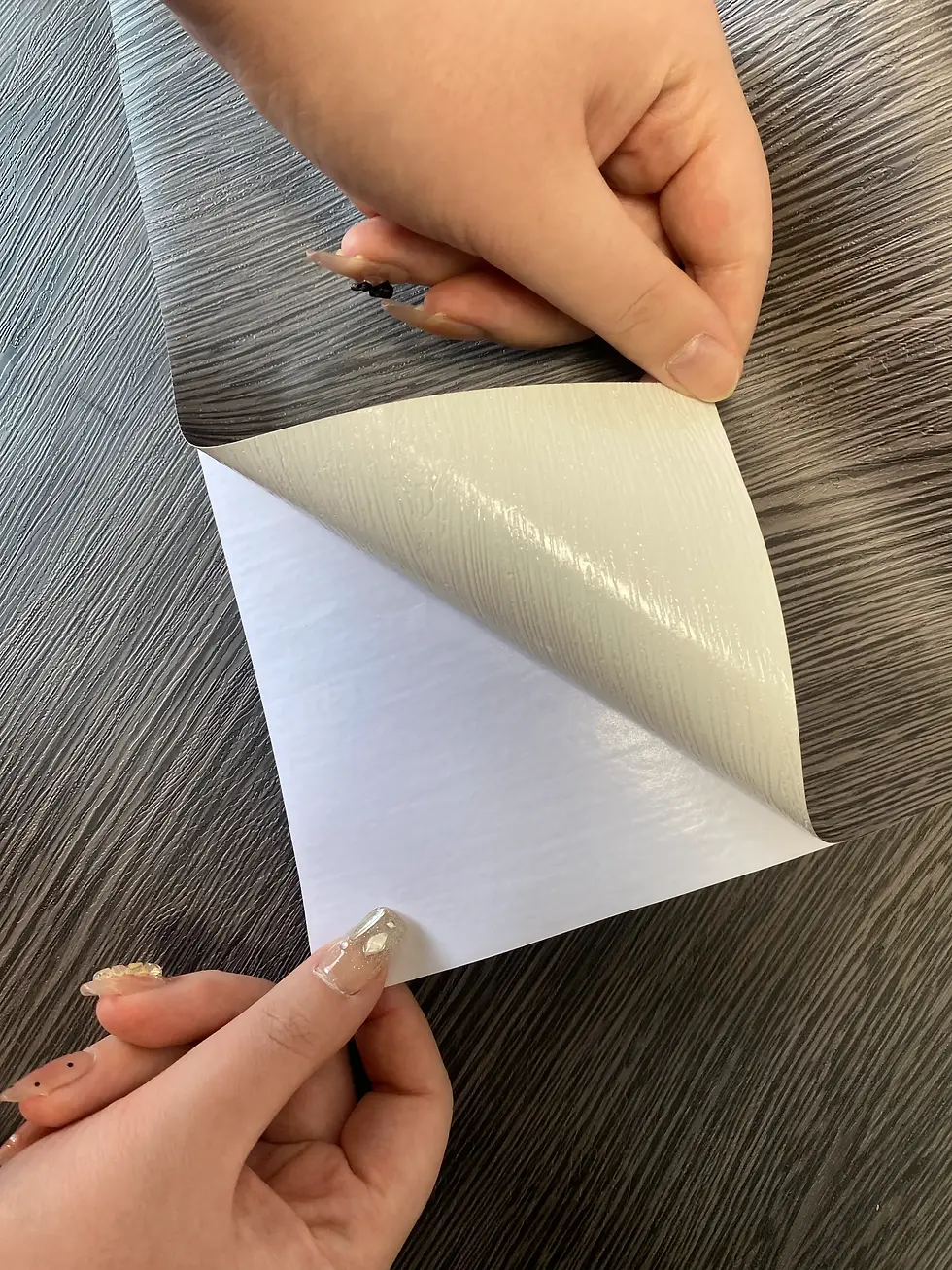

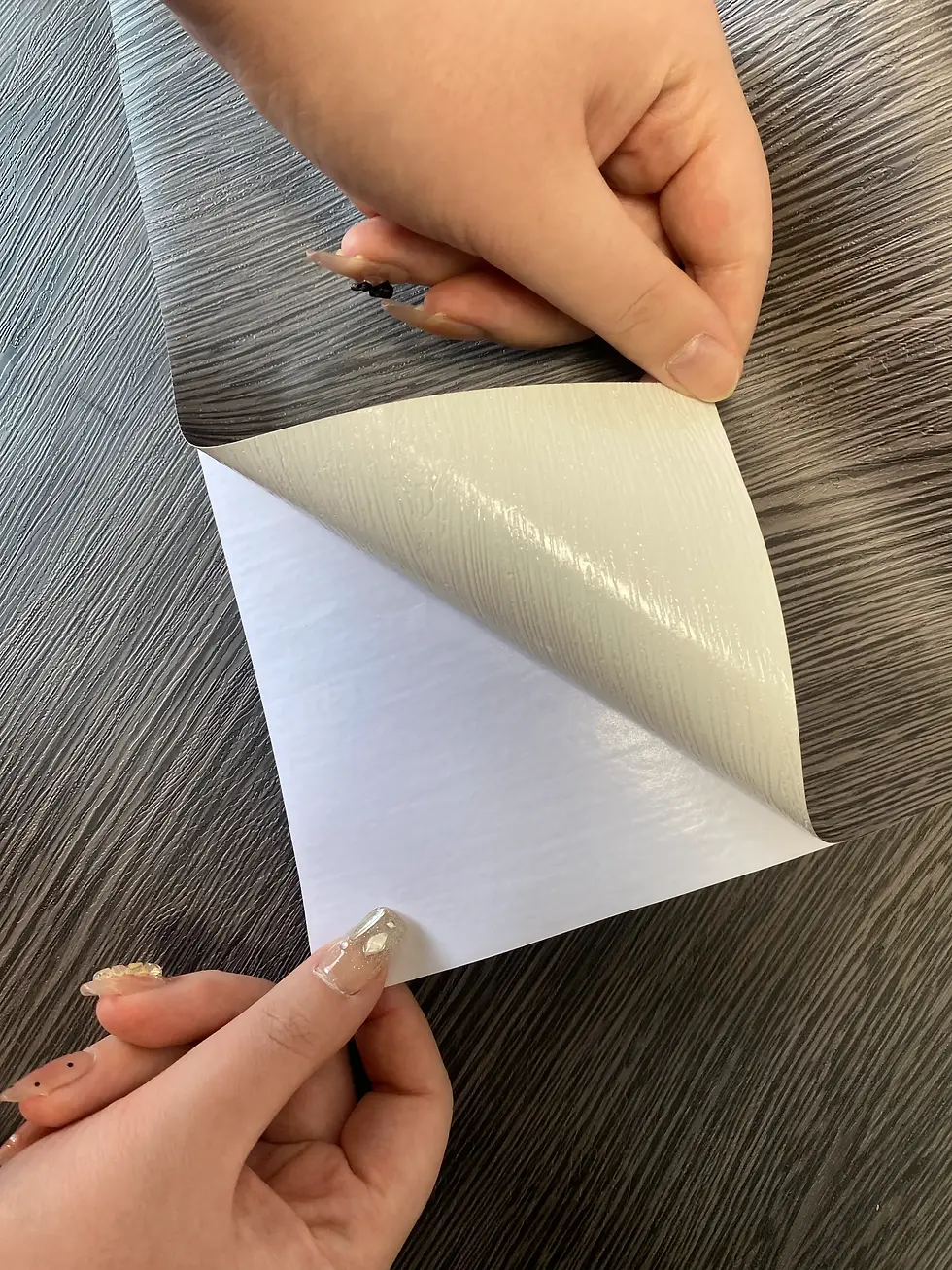

Adhesive: 90°/180° peel, loop-tack, shear creep, reworkability/clean-removal.

-

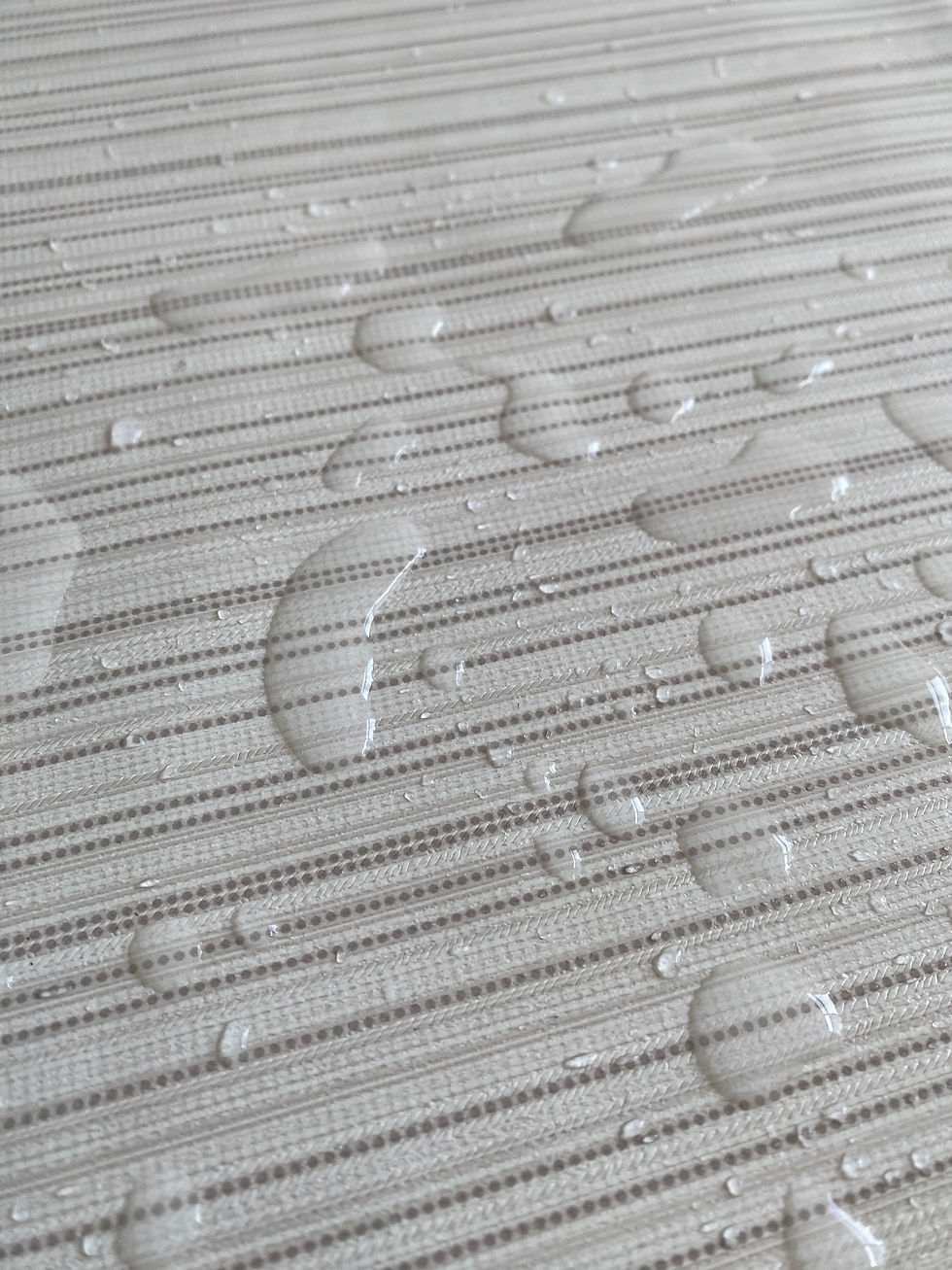

Optical & Surface: Spectrophotometer ΔE, gloss/haze, contact angle & dyne level.

-

Dimensional & Thermal: Gauge mapping, heat-shrink/flatness, cold-bend, thermal cycling.

-

Environmental & Chemical: QUV/UV, humidity/heat aging, stain/chemical resistance to cleaners, alcohols, disinfectants.

Sustainability Commitment

-

Low-VOC Chemistry: Water-based/low-solvent inks & coatings; solvent capture/recovery.

-

Resource Efficiency: Heat-recovery ovens, VFD motors, LED lighting, optimized curing profiles.

-

Waste Minimization: Trim segregation and re-granulation; planning to reduce changeover scrap.

-

Responsible Packaging: Recycled paper cores, right-sized cartons, reusable pallets.

-

Longer Service Life: Scratch-resistant, UV-stable films that enable refurbish-not-replace upgrades.