Why Are Fire-Retardant Decorative Films Essential for Middle East Projects?

- Dora

- Nov 28

- 4 min read

In the rapidly expanding construction and interior renovation markets of the Middle East, safety, durability, and regulatory compliance have become defining criteria for material selection. Across the Gulf region—including the UAE, Saudi Arabia, Qatar, Kuwait, Bahrain, and Oman—developers, contractors, architects, and material distributors are increasingly prioritizing solutions that meet strict fire safety standards while maintaining aesthetic versatility and installation efficiency. This demand has elevated fire-retardant decorative films from a niche category to a mainstream, must-have material in both commercial and residential projects.

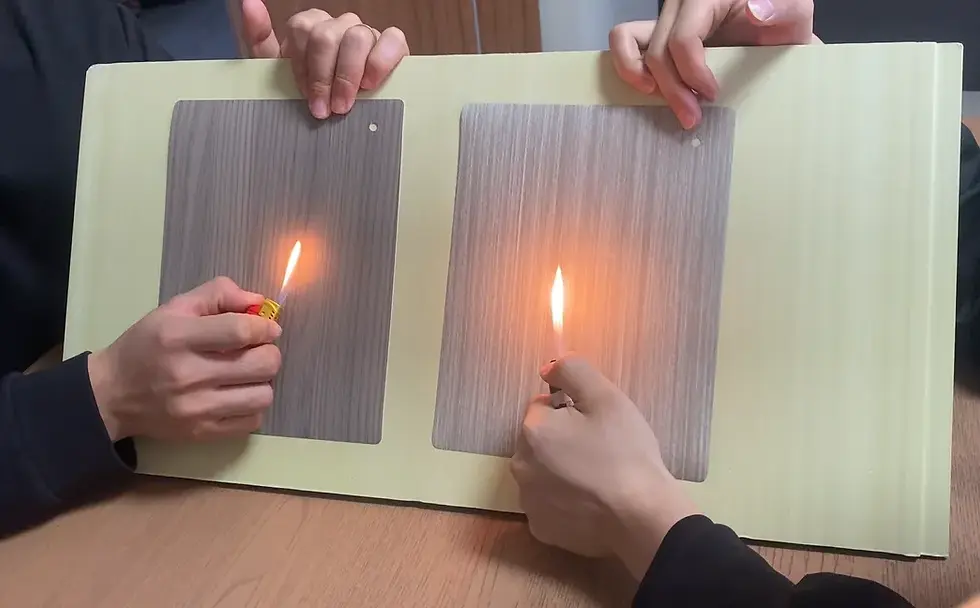

The essential role of fire-retardant decorative films in Middle Eastern projects stems first from the region’s unique climate and construction environment. High temperatures, often exceeding 45°C, accelerate material aging and increase fire risk in enclosed spaces. Traditional decorative materials such as low-grade PVC layers, laminates, wood veneer panels, or non-treated films not only degrade more quickly but may also release toxic fumes or burn rapidly when exposed to flames. In contrast, fire-retardant decorative films incorporate specialized formulations that significantly reduce flame spread, limit smoke density, and minimize secondary hazards—an advantage critical to meeting GCC building codes and improving occupant safety.

As governments strengthen building regulations, especially in hospitality, retail, healthcare, and large-scale public facilities, fire-resistant materials have become a prerequisite for project approval. Local authorities such as UAE Civil Defense, Saudi SASO, and Qatar Civil Defence enforce strict requirements for material classifications, often referencing internationally recognized standards like ASTM E84, EN 13501-1, and BS 476. Using certified fire-retardant decorative films helps contractors reduce the risk of approval delays, rework costs, and compliance disputes. Beyond regulation, major hotel groups, real estate developers, and high-end commercial operators now demand verifiable fire performance documentation before any material enters a building.

In addition to safety, fire-retardant decorative films are valued for their adaptability and compatibility with diverse substrates commonly used in Middle Eastern interiors. Whether applied to wooden doors, aluminum panels, gypsum partitions, MDF cabinetry, steel structures, or existing wall finishes, these films provide both fire protection and a high-quality aesthetic upgrade without adding bulk or requiring heavy construction. Their lightweight nature and ease of installation make them ideal for refurbishment projects where downtime must be minimized, such as hotel room upgrades, mall expansions, and office renovations. This efficient workflow aligns well with the fast-paced development cycles typical of GCC markets.

Durability is another major factor driving adoption. Middle Eastern interiors face constant exposure to heat, humidity, dust, and strong UV radiation—conditions that often cause yellowing, delamination, or surface cracking in inferior materials. High-quality fire-retardant decorative films are engineered with UV-resistant, heat-stabilized layers and adhesives designed specifically to maintain cohesion in extreme environments. For distributors and project managers, this stability reduces warranty claims and ensures long-term visual consistency, which is especially important for projects requiring ongoing replenishment or multi-phase construction.

One of the major commercial advantages of fire-retardant decorative films is their ability to combine safety and design flexibility. GCC markets favor a wide range of aesthetic finishes—from modern matte textures and super-gloss styles to deep woodgrains, marbles, concrete effects, and metallic laminations. Fire-retardant decorative films support all these design expressions without compromising performance. This flexibility allows developers to meet luxury design expectations while still complying with fire codes. Many brands, including Giwett, offer extensive pattern archives, custom finishes, and OEM/ODM services tailored to hotel chains, joinery factories, and large distributors who require exclusive collections.

To understand why fire-retardant films offer a superior value proposition for Middle Eastern projects, it is helpful to compare them with alternative materials commonly used in local markets:

Comparison of Fire-Retardant Decorative Films vs. Other Decorative Materials

Material Type | Fire Safety | Durability in High Heat | Installation Complexity | Maintenance | Cost Efficiency | Suitability for GCC Projects |

Fire-Retardant Decorative Films | Excellent (Class B / Class 1 options available) | High UV and heat resistance | Fast, clean, minimal downtime | Easy to clean, low maintenance | High value, low labor cost | Highly suitable; preferred for modern projects |

Standard PVC Films | Low | Weak under heat, prone to yellowing | Easy but not suitable for regulated projects | Moderate | Low upfront cost | Not suitable for commercial/hospitality applications |

Laminates (HPL) | Moderate | Good heat resistance | Requires carpentry & glue; slower installation | Durable | Higher material & labor cost | Suitable but less flexible for renovation |

Wood Veneer | Low to moderate | Sensitive to humidity & heat | Skilled installation required | High maintenance | High cost | Not ideal due to climate & fire codes |

Paint or Wall Coatings | Low unless fire-rated | Paint cracks in heat/humidity | Labor-intensive | Requires frequent repainting | Variable | Limited design versatility; not fire-safe |

The table highlights why fire-retardant decorative films stand out as the most balanced choice: they combine superior fire safety, environmental adaptability, cost-efficiency, and aesthetic variety. For contractors aiming to deliver compliant projects efficiently—and for distributors seeking high-demand, high-margin categories—these films provide a scalable solution with consistent performance.

From a business perspective, the rise in demand for fire-retardant decorative films presents a significant opportunity for Middle Eastern distributors and importers. The combination of stricter fire regulations, expanding hotel and residential developments, and increasing consumer preference for modern, clean design ensures sustained long-term growth for this category. Suppliers that offer verifiable testing reports, stable production capacity, and reliable color consistency—attributes central to Giwett’s manufacturing system—are well-positioned to support these growing markets. Giwett’s integrated R&D, coating, lamination, and embossing capabilities allow distributors to source customized finishes while ensuring repeat orders remain consistent across batches, which is critical for multi-phase building projects.

In conclusion, fire-retardant decorative films have become essential for Middle Eastern projects not only because they satisfy immediate fire safety requirements but also because they offer unmatched advantages in durability, aesthetic flexibility, installation efficiency, and compliance management. As GCC markets continue to enforce stricter material standards—and as developers increasingly prioritize safety with premium visuals—these films will remain a core material category for architects, contractors, and distributors seeking long-term value and consistent project outcomes.

Comments